HIGH SPEED AND FLEXIBILITY IN CON ROD MACHINING Minimized non-productive times - maximized production

Extremely short chip-to-chip time: The short travels guarantee an extremely low positioning time. Together with the main time parallel work piece loading and unloading as well as the quick tool change, the result is peak performance for a machine with the flexibility of a machining center and the high output of a special purpose machine.

CLAMPING FIXTURE Uncompromisingly flexible

The clamping fixture can be changed over to a new work piece type in very short time. This is possible due to a semi-automatic clamping plate change as well as exchange of tool and NC program.

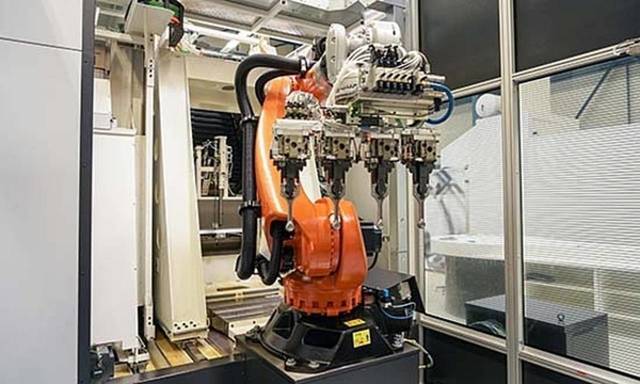

SPINDLE HEADS Uncompromisingly productive

Two spindle rows, which alternate in the machining process are arranged above each other and allow a main time parallel tool change.

ROBOT Uncompromisingly comfortable

In the future-orientated control concept of the AX 400, all robot functions are integrated in the machine control.

Machine and robot operate completely synchronously: during the machining process of the machine, the robot automatically follows the movements of the clamping fixture in the Y- and Z-axis. Loading and unloading thus is parallel to the main time.

TOOL MAGAZINE Uncompromisingly efficient

The tool magazine of the AX 400 consists of a drum-type magazine available within all 16 x 4 tool seats. The capacity is designed to provide redundant tool sets for the machining process.