Flexibility and Productivity in Con Rod Machining Uncompromisingly Specialized

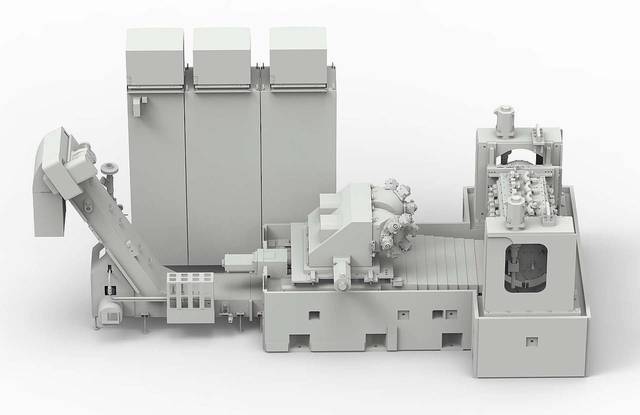

The AT 200 for Semi-Finish Machining of Con Rods

- Up to 4 fixture plates can be mounted for short change-over times

- Up to 2 turret heads with 4, 6 or 8 tools each

- Extremely short chip-to-chip time

- No chip problems at the tool interface thanks to the use of the tool turret

- High thermal stability

- High operator convenience

- Very good accessibility for maintenance and tool change

- Low space requirements on floor and in height

- Very versatile: Equipped with a Y-stroke of 630 mm it is a highly productive and process-safe alternative compared to a machining center

Clamping Fixture Uncompromisingly Flexible

The clamping fixture swivels around the A-axis and can be moved linearly in Y-direction. It can be quickly changed over and allows a clamping sequence freely programmable in the NC program. Due to the high flexibility, it offers the possibility to quickly, easily and cost-efficiently produce different work pieces on the machine. Thanks to the four sided tombstone concept, up to 4 different component types can be machined without any change-over.

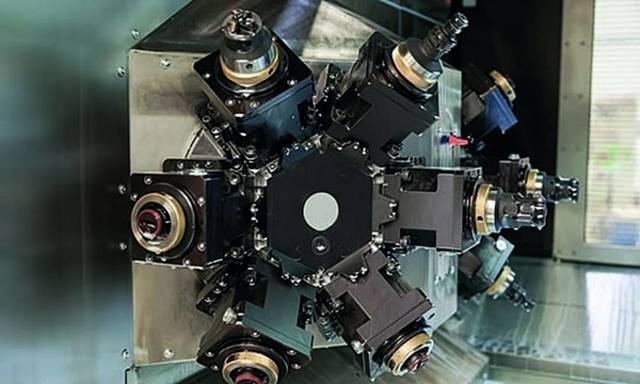

Turret Boring Heads Uncompromisingly Variable

Up to two turret heads can be placed onto the slide moving in X- and Z-direction. Thus, work pieces can be machined parallel, significantly increasing the total output.